ALTERNATIVE TO TEAROFFS REDUCE WASTE- ALLOWED ON ALL TRACKS

LENS PROTECTOR

RIPCLEAR MOTO LENS PROTECTOR

PROTECT YOUR LENS!RIPCLEAR PROTECTION

Ripclear is an industry leading manufacturer of protective goods for optics components, and PPE products. With over 10 million units of PPE sold across the globe, Ripclear has an established presence and a reputation for quality products.

Serving businesses, as well as direct-to-consumer, our mission is to help you stay healthy and protected.

POPULAR PRODUCTS - LENS PROTECTORS

-

Ripclear Universal Large Spherical Snow Goggle Lens Protector - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Universal Moto Goggle Lens Protector - 2 Pack - Tear Off Replacement - Allowed At All Tracks And Trails! - Fits All Lens - FREE SHIPPING

Regular price $12.97 USDRegular priceUnit price / per -

100% Armega Moto Goggle Lens Protector - 2 Pack - Trash Reduced Tear Off Alternative

Regular price $12.97 USDRegular priceUnit price / per -

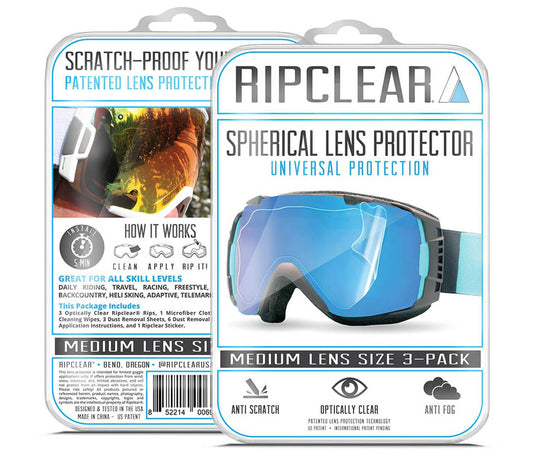

Ripclear Spherical Universal Medium Snow Goggle Lens Protector - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear 100% Accuri-Strata-Accuri 2-Strata 2 Moto Goggles Lens Protector

Regular price $12.97 USDRegular priceUnit price / per -

Ripclear Oakley Fall Line XL Snow Goggle Lens Protector - 2 Pack

Regular price $14.99 USDRegular priceUnit price / per -

(Universal Fit) Smith Squad Snow Goggle Lens Protector (Universal Fit) - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Universal Mountain Bike Goggle Lens Protector - 2 Pack

Regular price $12.97 USDRegular priceUnit price / per -

Ripclear Goggle Lens Cleaning Kit

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear Oakley Line Miner Snow Goggle Lens Protector - 2 Pack

Regular price $24.99 USDRegular priceUnit price / per -

Ripclear Cylindrical Medium Universal Snow Goggle Flat Lens Protector - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear Cylindrical Small Universal Snow Goggles Flat Lens Protector - 3 Pack

Regular price $29.99 USDRegular priceUnit price / per -

Ripclear Cylindrical Large Universal Snow Goggle Lens Protector - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

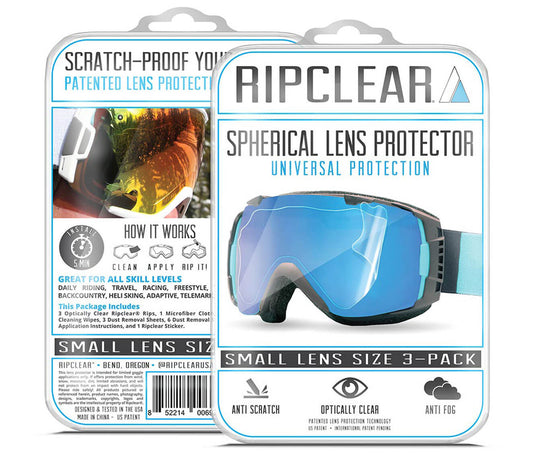

Ripclear Spherical Universal Small Snow Goggle Lens Protector - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Universal Kids Moto Goggle Lens Protector - 2 Pack - TEAR OFF ALTERNATIVE - CUT TO FIT ALL YOUTH GOGGLES - ALLOWED AT ALL TRACKS - FREE EXPRESS SHIPPING

Regular price $9.97 USDRegular priceUnit price / per -

Eyeglass Cleaning Kit With Glasses Bag

Regular price $14.99 USDRegular priceUnit price / per -

Sunglass Cleaning Kit With Glasses Bag

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear Smith I-O7 Snow Goggle Lens Protector - 2 Pack

Regular price $24.99 USDRegular priceUnit price / per -

Ripclear Spy Optic Ace Snow Goggle Lens Protector (Universal Fit) - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear Poc Retina Snow Goggle Lens Protector - 2 Pack

Regular price $24.99 USDRegular priceUnit price / per -

Ripclear Oakley Fall Line Snow Goggle Lens Protector - 2 Pack

Regular price $24.99 USDRegular priceUnit price / per -

Ripclear Dragon NFX Snow Goggle Lens Protector - 2 Pack

Regular price $24.99 USDRegular priceUnit price / per

PROTECT YOUR WORKFORCE WITH

RIPCLEAR FACE SHIELDS

FDA, CE, & ISO CERTIFIED

PRODUCTS LENS PROTECTORS

-

Ripclear Universal Large Spherical Snow Goggle Lens Protector - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Universal Moto Goggle Lens Protector - 2 Pack - Tear Off Replacement - Allowed At All Tracks And Trails! - Fits All Lens - FREE SHIPPING

Regular price $12.97 USDRegular priceUnit price / per -

100% Armega Moto Goggle Lens Protector - 2 Pack - Trash Reduced Tear Off Alternative

Regular price $12.97 USDRegular priceUnit price / per -

Ripclear Spherical Universal Medium Snow Goggle Lens Protector - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear 100% Accuri-Strata-Accuri 2-Strata 2 Moto Goggles Lens Protector

Regular price $12.97 USDRegular priceUnit price / per -

Ripclear Oakley Fall Line XL Snow Goggle Lens Protector - 2 Pack

Regular price $14.99 USDRegular priceUnit price / per -

(Universal Fit) Smith Squad Snow Goggle Lens Protector (Universal Fit) - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Universal Mountain Bike Goggle Lens Protector - 2 Pack

Regular price $12.97 USDRegular priceUnit price / per -

Ripclear Goggle Lens Cleaning Kit

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear Oakley Line Miner Snow Goggle Lens Protector - 2 Pack

Regular price $24.99 USDRegular priceUnit price / per -

Ripclear Cylindrical Medium Universal Snow Goggle Flat Lens Protector - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear Cylindrical Small Universal Snow Goggles Flat Lens Protector - 3 Pack

Regular price $29.99 USDRegular priceUnit price / per -

Ripclear Cylindrical Large Universal Snow Goggle Lens Protector - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear Spherical Universal Small Snow Goggle Lens Protector - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Universal Kids Moto Goggle Lens Protector - 2 Pack - TEAR OFF ALTERNATIVE - CUT TO FIT ALL YOUTH GOGGLES - ALLOWED AT ALL TRACKS - FREE EXPRESS SHIPPING

Regular price $9.97 USDRegular priceUnit price / per -

Eyeglass Cleaning Kit With Glasses Bag

Regular price $14.99 USDRegular priceUnit price / per -

Sunglass Cleaning Kit With Glasses Bag

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear Smith I-O7 Snow Goggle Lens Protector - 2 Pack

Regular price $24.99 USDRegular priceUnit price / per -

Ripclear Spy Optic Ace Snow Goggle Lens Protector (Universal Fit) - 3 Pack

Regular price $14.99 USDRegular priceUnit price / per -

Ripclear Poc Retina Snow Goggle Lens Protector - 2 Pack

Regular price $24.99 USDRegular priceUnit price / per -

Ripclear Oakley Fall Line Snow Goggle Lens Protector - 2 Pack

Regular price $24.99 USDRegular priceUnit price / per -

Ripclear Dragon NFX Snow Goggle Lens Protector - 2 Pack

Regular price $24.99 USDRegular priceUnit price / per

Blogs

-

Clarity Matters: The Crucial Importance of Clea...

Sunglasses are more than a stylish accessory – they are a shield for our eyes, protecting them from harmful UV rays while adding a touch of personality to our look....

Clarity Matters: The Crucial Importance of Clea...

Sunglasses are more than a stylish accessory – they are a shield for our eyes, protecting them from harmful UV rays while adding a touch of personality to our look....

-

Clarity Matters: Pioneering Sunglass Care with ...

Sunglasses are more than just a style statement; they're essential for protecting our eyes from the sun's harsh rays. As we embark on the journey of understanding the critical importance...

Clarity Matters: Pioneering Sunglass Care with ...

Sunglasses are more than just a style statement; they're essential for protecting our eyes from the sun's harsh rays. As we embark on the journey of understanding the critical importance...

-

Crystal Clear Vision: Nurturing Your Sunglasses...

ntroduction: Sunglasses are more than just a fashion accessory – they're our loyal companions, shielding our eyes from the sun's harsh rays while adding a touch of style to our...

Crystal Clear Vision: Nurturing Your Sunglasses...

ntroduction: Sunglasses are more than just a fashion accessory – they're our loyal companions, shielding our eyes from the sun's harsh rays while adding a touch of style to our...